From the collection of raw materials to customer delivery, each stage is fully mastered, with machinery that has been exclusively designed for OMNI-PAC GROUP and a culture of operational excellence motivated by performance and customer satisfaction.

To produce its eco-friendly packaging, OMNI-PAC GROUP sources recycled paper and cardboard as raw materials. We are committed to promoting sustainable practices and reducing waste by giving a second life to used paper products. In fact, the group recycles more than 100,000 tonnes of used paper each year, which not only reduces the amount of waste going to landfills but also conserves natural resources and energy that would have been used to produce new paper.

By using recycled materials, OMNI-PAC GROUP is able to contribute to a more sustainable future while also producing high-quality, reliable packaging for its customers.

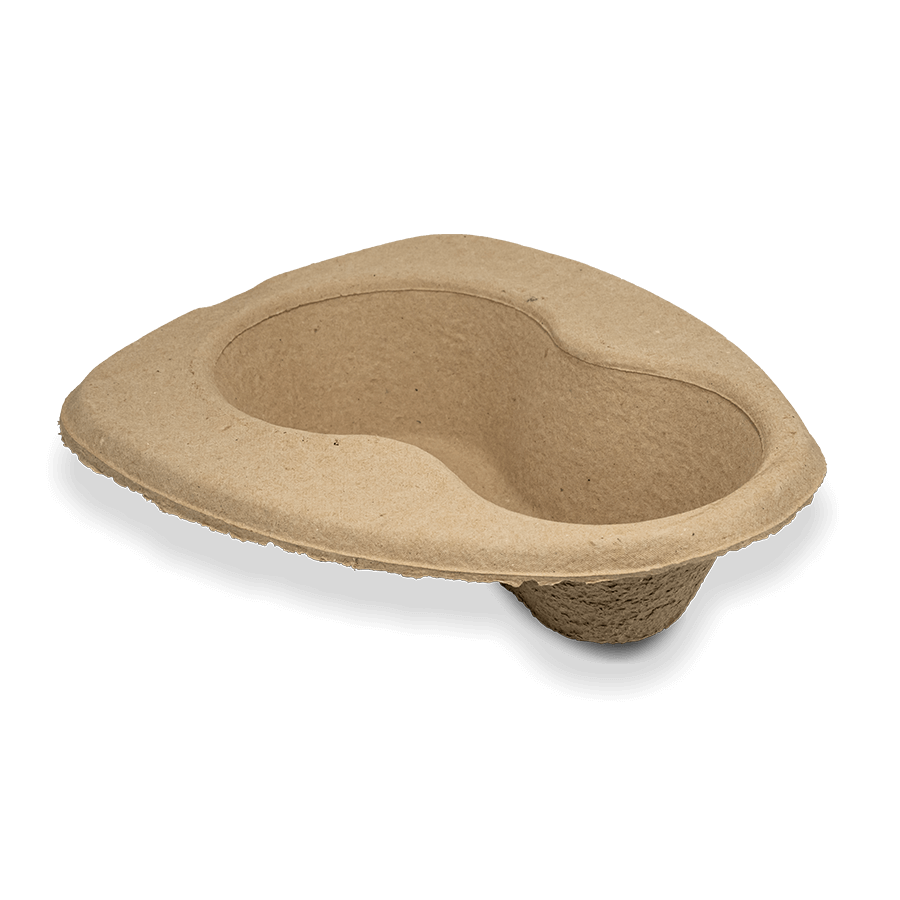

The tool-making process stage in the production of moulded fibre packaging is critical to the overall quality and functionality of the final product. During this stage, the fibrous pulp is subjected to a suction and pressure process that enables it to adhere to a screen, forming a damp and moist fibre web that can be shaped into the desired form. This process requires precision and expertise to ensure the fibrous pulp is shaped correctly, without defects or deformities.

To ensure the quality and precision of this stage, OMNI-PAC GROUP has an internal design and production team responsible for creating the necessary tools and equipment for the shaping process. This team is highly skilled and experienced in designing and building custom tools that are tailored to the specific needs of each customer and product.

OMNI-PAC GROUP can ensure rapid turnaround times, high-quality products, and competitive pricing for its customers by keeping this process in-house.

OMNI-PAC GROUP can create custom moulds to meet the specific requirements of a product application. This means that we can design and produce moulds tailored to the unique shape and size needs of a customer's product.

With this level of customisation, we can ensure that the packaging is optimised for the product, providing maximum protection and efficiency during transport and storage.

Automating the packing lines at OMNI-PAC GROUP allows for increased efficiency and accuracy while reducing the risk of human error. Finished goods are weighed and itemised using barcodes, ensuring that each pallet is packed with the correct quantity of products and is properly labelled. This automation is closely monitored by experienced teams to ensure that everything runs smoothly and to address any issues that may arise.

By implementing this automated system, OMNI-PAC GROUP is able to stay competitive in the market and maintain a high level of quality and customer satisfaction.

Flixborough Industrial Estate

Scunthorpe

DN15 8SD, UK

+44 (0)1724 847 207

Rue Pierre Clugnet

56350 Allaire

FRANCE

+33 (0)2 99 71 95 22

An der Kaje 1

26931 Elsfleth

GERMANY

+49 (0) 4404 9874-0

Designed to your specification, we can produce customised, recyclable moulded fibre products for a range of industries. With over 50 years of expertise in our field, we work alongside you to bring your ideas to life and exceed your expectations.