OMNI-PAC GROUP is one of the leading manufacturer and supplier of moulded pulp packaging products. We use the latest conventional pulp fibre moulding equipment and unique after-pressing technology to achieve fantastic results.

OMNI-PAC GROUP is committed to environmental sustainability and takes this responsibility seriously. We believe that it is important to act now to mitigate the harmful impact of plastic packaging on the environment.

By using materials such as recycled paper and cardboard, we reduce the impact on the environment and promote the circular economy. Additionally, we offer eco-responsible packaging options such as natural, recyclable, and compostable packaging, which helps to reduce waste and promote responsible consumption.

We are constantly exploring new ways to further reduce our environmental footprint and promote sustainable practices throughout our business.

The green packaging solutions provided by OMNI-PAC GROUP are an environmentally-friendly alternative to plastic packaging. They are made from recycled paper and cardboard and are fully biodegradable, recyclable, and compostable. This means that they can be disposed of in an eco-friendly manner, without harming the environment.

Furthermore, all of OMNI-PAC GROUP's moulded pulp products are manufactured at our facility in North Lincolnshire, UK. By producing our products locally, we are able to minimise our carbon footprint and reduce our impact on the environment. Additionally, by manufacturing our products in-house, allows OMNI-PAC GROUP to have greater control over the production process and ensure that our products are of the highest quality.

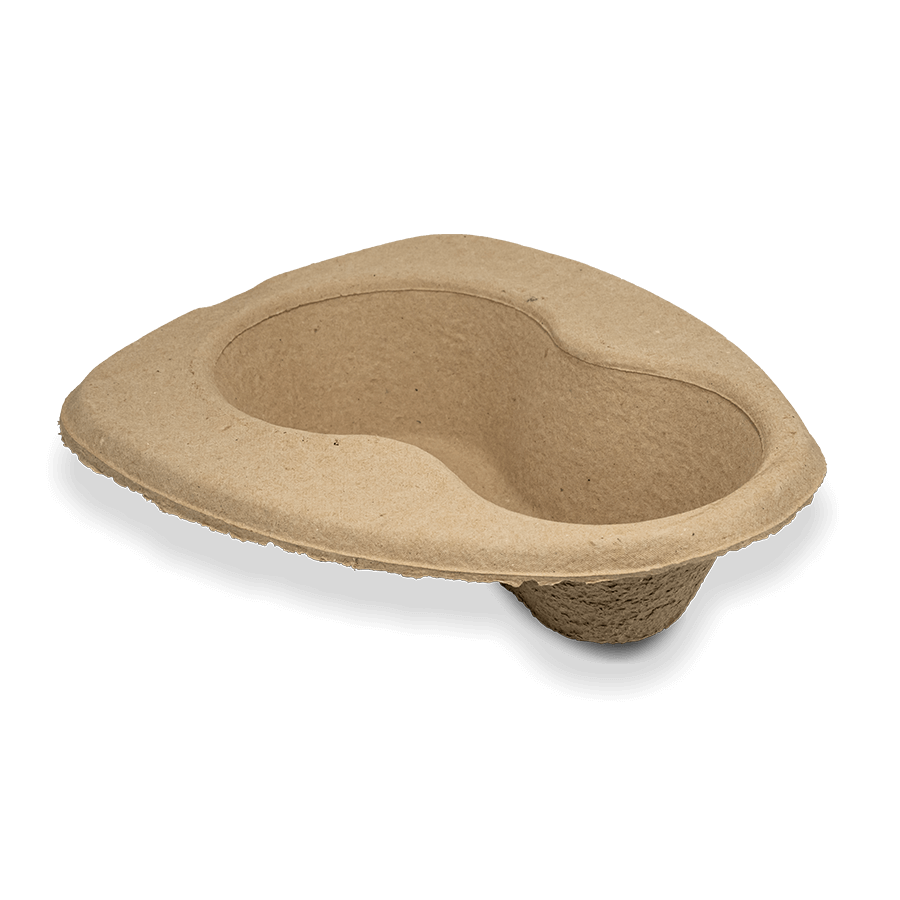

Moulded pulp packaging is a sustainable and eco-friendly solution that helps to reduce the amount of waste that ends up in landfills. At OMNI-PAC GROUP, we use recycled paper and cardboard to create our moulded fibre products, which are biodegradable, compostable, and recyclable.

Our Wet Pressing Technology is used to combine the recycled cardboard with water to create a slurry, which is then formed into the desired shape using moulds. This process provides strength and rigidity to the final product.

Using moulded fibre products as an alternative to plastic packaging is an important step towards sustainability. By using a surplus of cardboard, we are giving new life to materials that would otherwise end up in the waste stream. Plus, our moulded pulp packaging can be easily recycled or composted at the end of its use, reducing the environmental impact even further.

ISO 9001 is an international standard that sets out the criteria for a quality management system. By meeting this standard, OMNI-PAC GROUP ensures that its processes and procedures consistently meet the needs of customers and stakeholders while also striving for continuous improvement.

This standard places a strong emphasis on customer satisfaction and requires companies to have a customer-focused approach to their business.

By adhering to the requirements of ISO 9001, OMNI-PAC GROUP demonstrates its commitment to providing high-quality products and services while continually seeking ways to enhance its operations.

The BRCGS® standard is a leading global brand and consumer protection organisation, widely recognised for setting the benchmark for good manufacturing practices in food safety, packaging, storage, and distribution. The BRCGS® certification is a globally recognised standard that indicates that a company, such as OMNI-PAC GROUP, has implemented and adhered to stringent food safety and quality management systems, as well as appropriate risk management procedures.

This ensures the safety and quality of food products throughout the entire supply chain. The BRCGS® standard is regularly updated and reviewed to keep up with industry developments and is recognised by major retailers, manufacturers, and food service companies worldwide.

By achieving BRCGS® certification, OMNI-PAC GROUP demonstrates its commitment to food safety, quality, and continuous improvement, and provides customers with the assurance that their products meet the highest standards.

We aim to supply moulded pulp products which will exceed your expectations when it comes to quality, value and service. Over 50 years’ experience in making world-class, 100% recyclable, eco-friendly packaging for all industries.

Designed to your specification, we can produce customised, recyclable moulded fibre products for a range of industries. With over 50 years of expertise in our field, we work alongside you to bring your ideas to life and exceed your expectations.

Together we can endTake > Make > Waste

When we talk about ‘take-make-waste’, what we’re referring to is an approach to resources. This model is the basis of the linear economy, in which raw materials are collected, transformed into products which are used briefly, and then thrown away. Take, make, waste.

Circular economy is an alternative framework for designing, making and using things that is kinder to the environment. Unlike the linear economy, it is restorative and regenerative by design, and prevents waste by recovering and reusing as many products and materials as possible. In other words, the circular economy tries to embed things in cycles: take, make, use, consume, regenerate, restore, reuse.

All our environmentally friendly products ensure the sustainable management of our environmental resources and are employed in a raw material cycle.

Flixborough Industrial Estate

Scunthorpe

DN15 8SD, UK

+44 (0)1724 847 207

Rue Pierre Clugnet

56350 Allaire

FRANCE

+33 (0)2 99 71 95 22

An der Kaje 1

26931 Elsfleth

GERMANY

+49 (0) 4404 9874-0